Robotics has gone a long way. We have found numerous uses for them. The robots we make are now part of our society in a way that improves how we live in the world today.

So what are the uses of these robots? From the medical, military, and domestic fields, each field now has a robotic counterpart to easily do tasks. At the same time, they improve the way people do things that they feel are too menial, hard, or dangerous to do for humans. However, it doesn’t mean that humans are no longer needed in these tasks. Robots still need human supervision to bring out their full potential.

One of these uses is in the industrial front. The reason is most factories have now mechanized their workforce to manufacture products faster and more precisely than a person. This results in a more precise finish on many products with only the slightest of errors. However, in all ways of using robotics, they still require a human touch to perform well. Moreover, it’s doubtful if it can be done at all if the human element is removed from these aspects of manufacturing.

Robots Used In Industry And Manufacturing And Their Uses

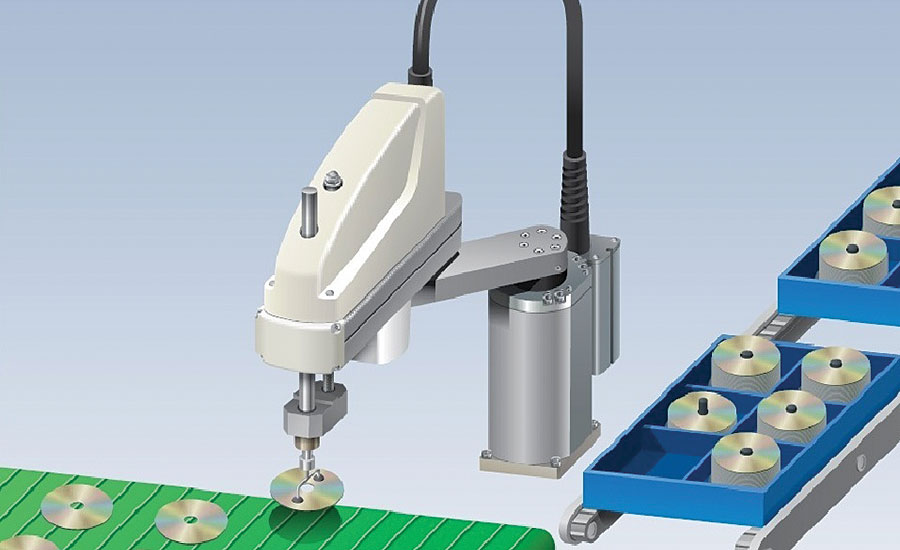

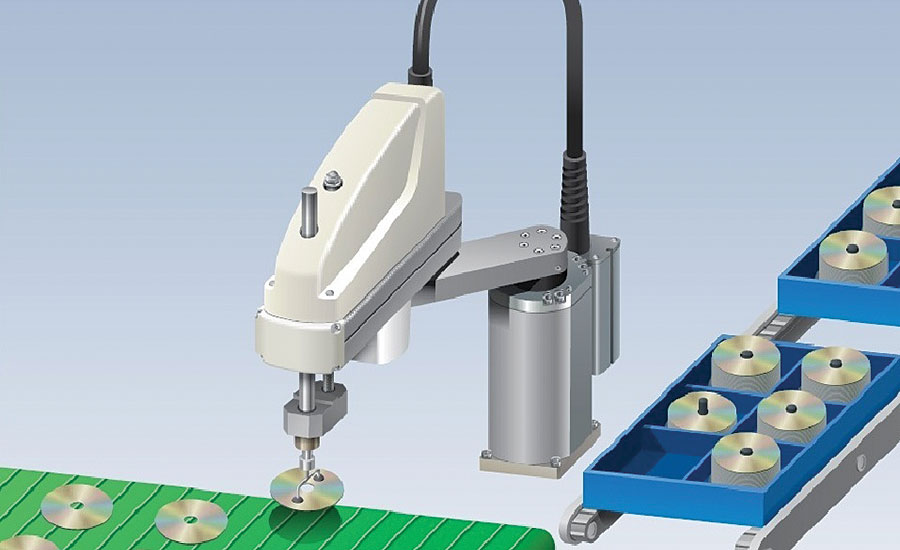

SCARA

SCARAs are all in one robot. They come with an x, y, z, and rotary motion in one package that comes ready-to-use, apart from the end-of-arm tooling. Their work envelope is cylindrical but with more degrees of motion in a radius or arch-shaped space. SCARA robots are often visible in BioMed applications due to their small work area. With SCARA having the easiest integration, it would seem like the best robot type for the majority of applications. However, another type of robot is more common due to the level of customization that it has.

Cartesian

Also called rectilinear and gantry robots and named after a famous mathematician. They are the most common type of robots used in manufacturing and industry. These industrial robots are one of the most popular choices by most plant operators because it is easy to use and program. The linear movements give it a cube-shaped workspace that fits best with pick-and-place applications and can range from 100 millimeters to tens of meters. Customers can determine the lengths, speed, and precision of the robots. This is because most of the parts arrive separately and already assembled by the machine builders.

It does have one drawback though, and that’s how complex it is to assemble. Overall though, most plant operators will choose this robot design due to how flexible it’s configurations are in meeting the needs of their workplace.

6-Axis

6-axis robots come in all shapes and sizes. They can be toy-sized. However, they are typically very large and used in all sorts of big assembly jobs like placing car seats on cars in assembly lines. They operate almost like a human arm and can pick up materials and move them from one place to another with incredible precision – something most robot types can’t do easily. 6-axis robot types have the capability of moving quickly and come up in complete solutions. However, their programming is more complicated. Due to how they come in all shapes and sizes and on how quick they are, most designers use them for their ability to make movements that others cannot do to compensate for the loss of space.

Cylindrical

Cylindrical robots are pretty similar to the Cartesian robot type in terms of their axis of motion. Most of them are made from two moving elements: rotary and linear actuators. Their simple installation and usage, alongside its cylindrical work envelope, is the reason for most machine designers to use them for their economy of space. It can be placed anywhere, even in the middle of a workspace due to the rotary design. Furthermore, simple applications are where this robot type shows its capabilities best.

Delta

Delta robots are the fastest and most expensive in industrial robotics shown here. Spider-like in appearance, their unique, dome-shaped envelope allows them to work at a very fast speed. They’re best for fast, pick-and-place, or product transfer applications like moving parts from one conveyor belt to another. They also come as complex solutions for machine designers. However, they are incredibly complicated to use compared to the examples above. Their main advantage is the speed at which they operate.

What Best Fits Your Manufacturing Needs

When designers are deciding to implement one of these robot types in their processes, they need to consider the basic starting points for any motion application. These points include load, speed, orientation, environment, precision, travel, and duty cycle. Determining these factors will draw different correlations to the corresponding type of robot that will give them the most efficient and effective results in their manufacturing facility.